Overview

Components:

- Beams & Columns: Hot-rolled or built-up steel sections that bear the vertical and horizontal loads.

- Rafters: Sloped members forming the roof structure, essential for load transfer.

- Rigid Frames: Most common primary framing type, especially for industrial sheds and warehouses.

Key Facts & Industry Trends

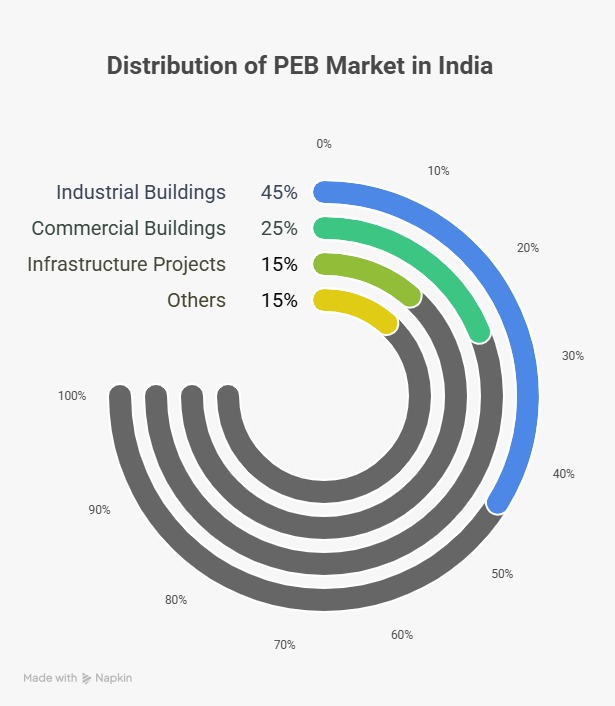

1. Demand Driven by Industrial Growth

- Primary frames account for 30–40% of total steel consumption in PEB structures.

- Usage is highest in logistics parks, warehouses, cold storage units, and data centers.

- in E-commerce warehousing and last-mile logistics hubs is pushing structural steel demand.

2. High Strength-to-Weight Ratio

- Built-up sections in PEB frames offer up to 30% steel savings over conventional RCC structures.

- Modular designs enable faster fabrication and erection (up to 40–50% time saved).

3. Customization & Scalability

- Frames can be customized for:

- Clear span buildings (up to 60 meters)

- Crane-supporting structures

- Multi-gable or multi-span buildings

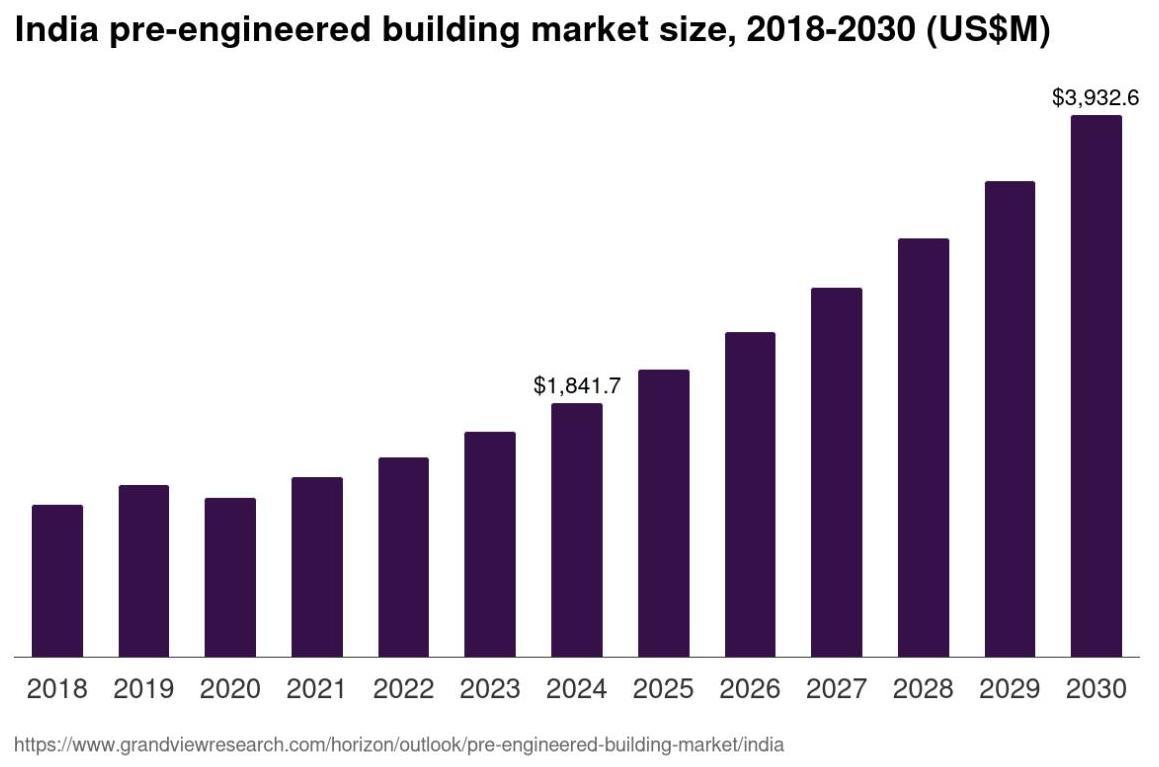

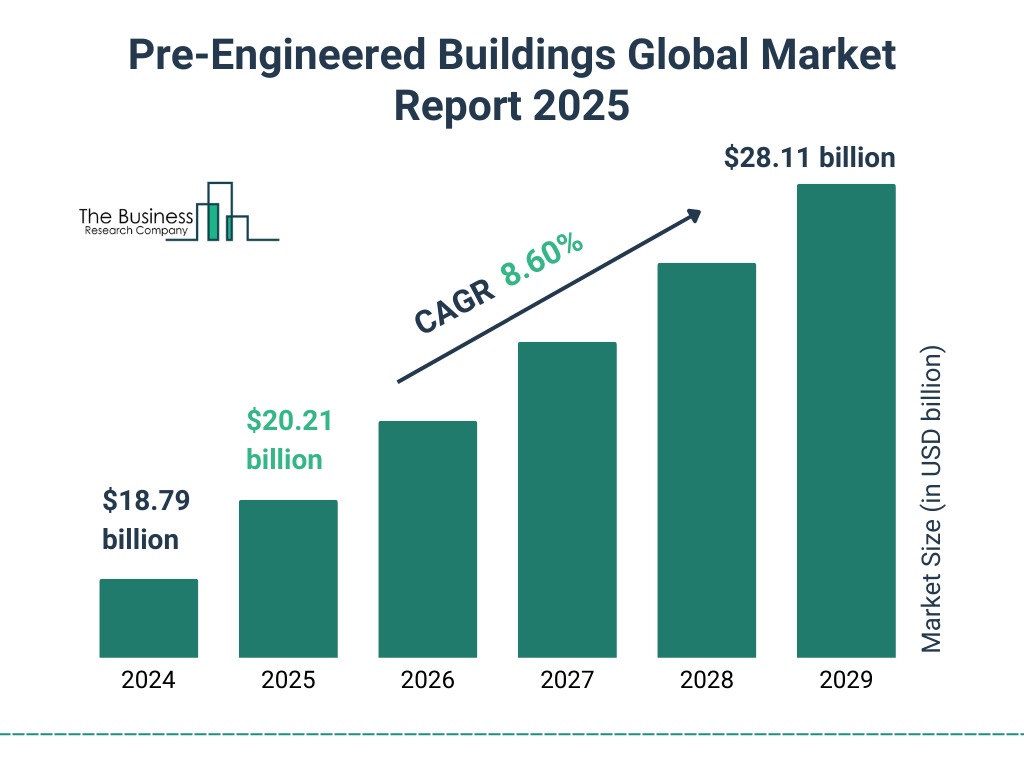

Stats & Charts

Opportunities in the Indian PEB Sector (Primary Framing Focus).

1. Expansion into Tier-2 & Tier-3 Cities

- Demand is growing in smaller cities for industrial parks, warehouses, and smart factories.

2. Government Infrastructure Initiatives

- PM Gati Shakti, Bharatmala, and Make in India push are boosting infrastructure development and increasing steel frame demand.

3. Replacement of Conventional RCC

- Industries are rapidly switching from RCC to PEB for:

- Lower lifecycle costs

- Faster return on investment

- Lower foundation loads

4. Green Construction & Energy Efficiency

- High recyclability of steel and better insulation design in PEB frames align with green building norms.

5. Public Sector Demands

- Expansion in railway stations, airports, metro depots, and logistics terminals using PEB frameworks.